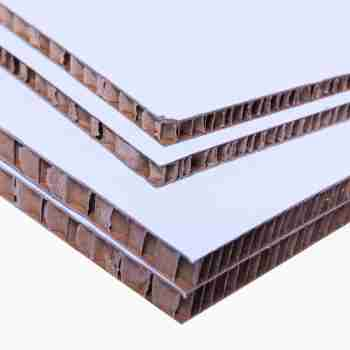

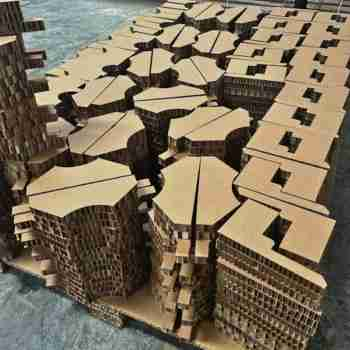

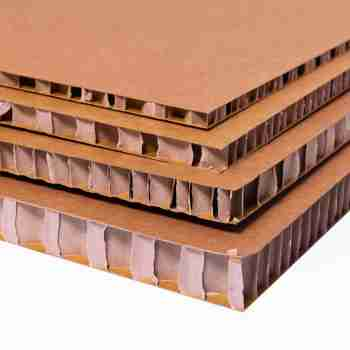

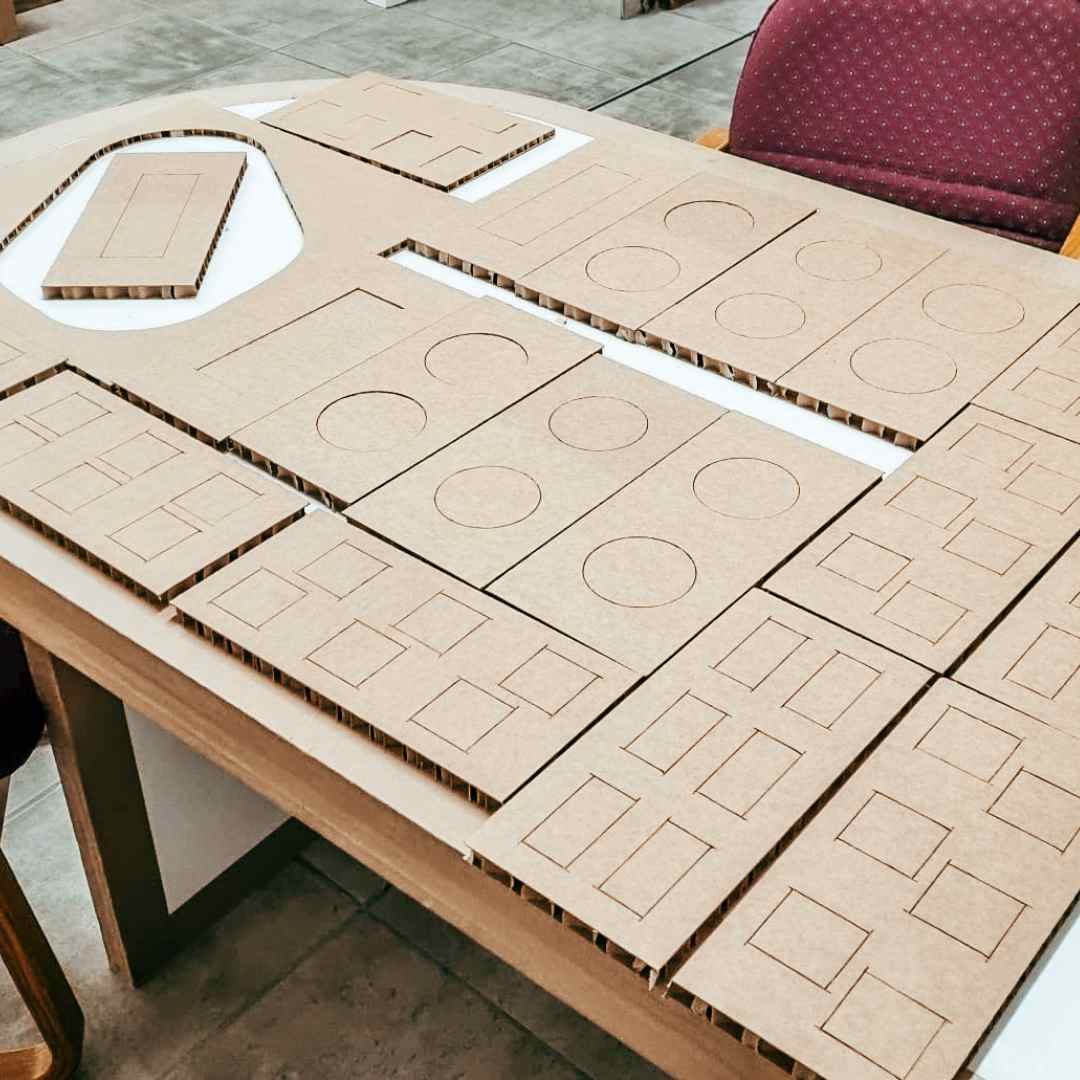

Rebul makes kraft and graphic honeycomb boards. We create these boards by shaping kraft paper. This process forms a series of triangular cells. The result is a strong paper honeycomb core. After that, the paper honeycomb core is laminated with kraft paper on both sides. Creating strong boards that can handle compressive, shear, and bending loads. These boards are up to 80% lighter than traditional materials.

Their strong crush to strength ratio makes the boards a cost-effective option. This is beneficial for designers, manufacturers, and board converters. You can learn more about this

alternative. This is especially true when fiberglass, medium-density fiberboard (MDF), foam, and plywood boards are too expensive or heavy.

The boards are lightweight, versatile, and easy to work with. To practically fit any purpose, they can be bonded to a range of facing materials, painted, printed on, sized, cut, shaped, and bent. Can be easily cut using a knife, handsaw or electric saw, and CNC depending on desired use, capability, and application.